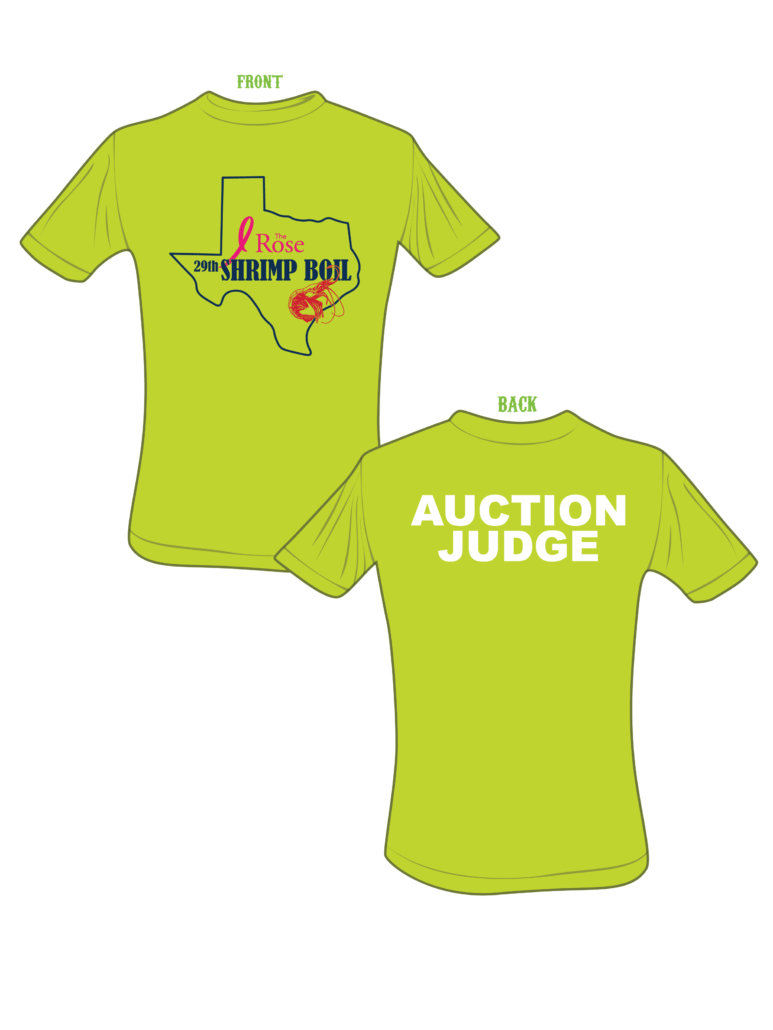

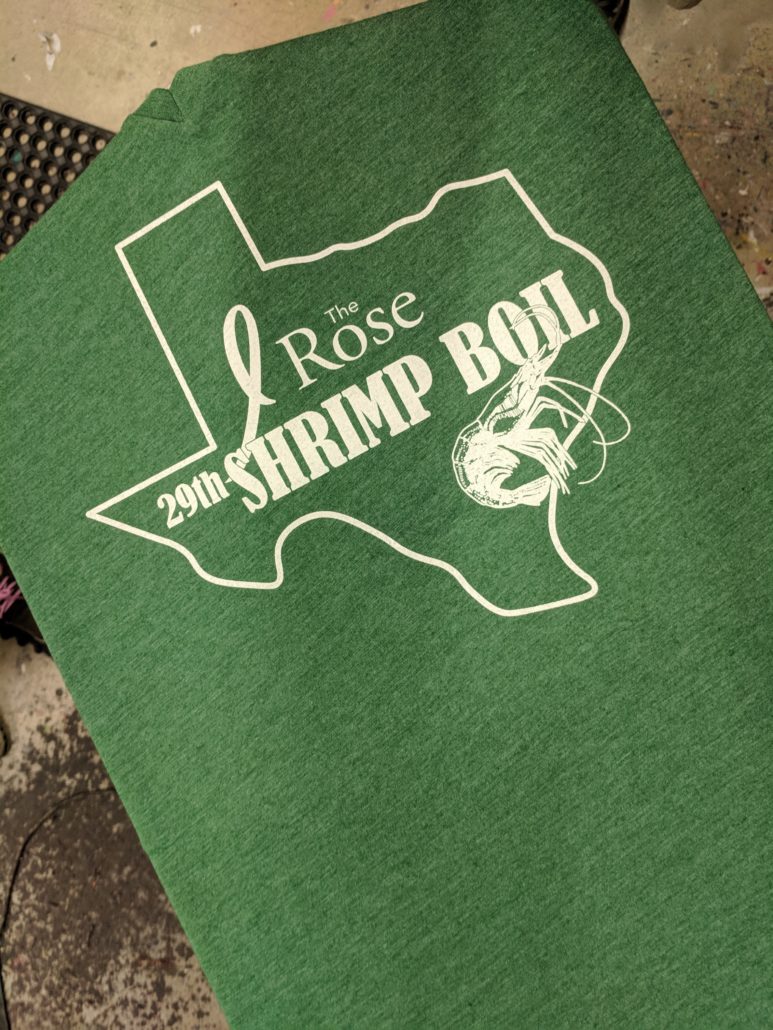

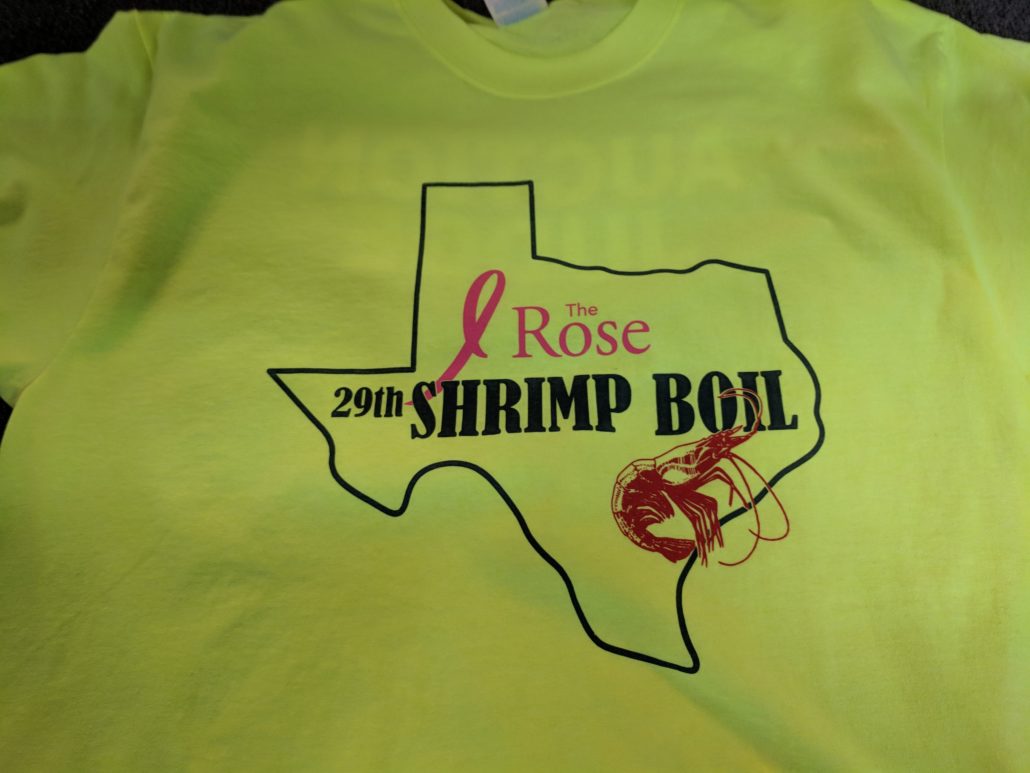

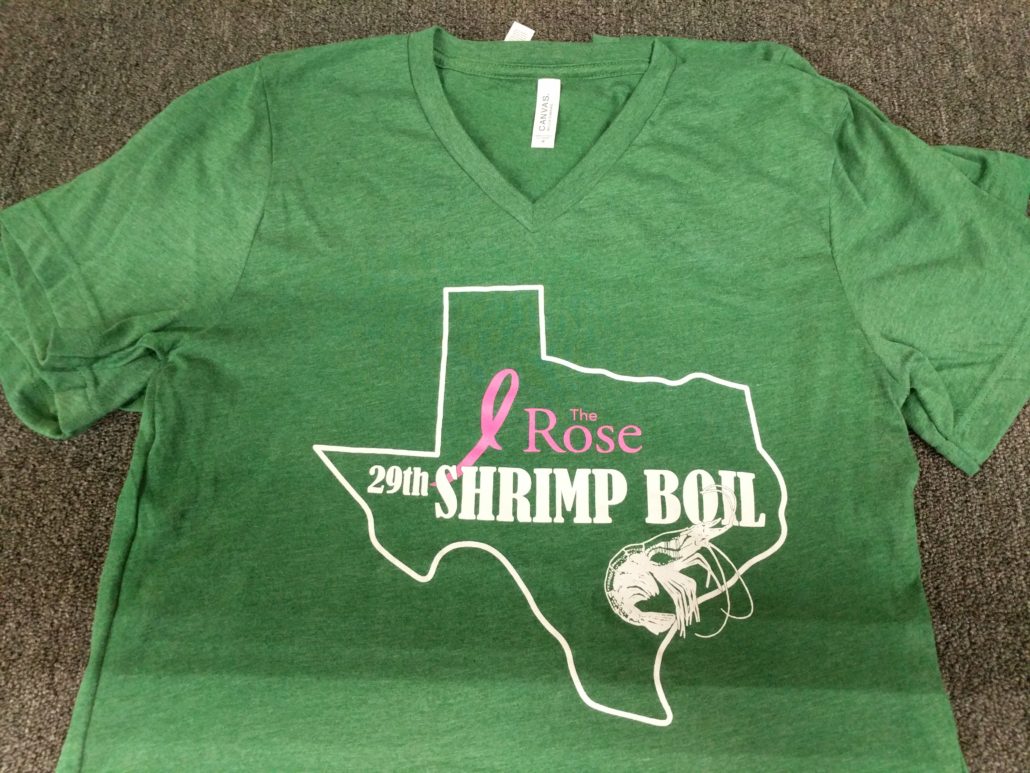

We start with digital artwork proofs. These are the two shirts and designs we ended up with.

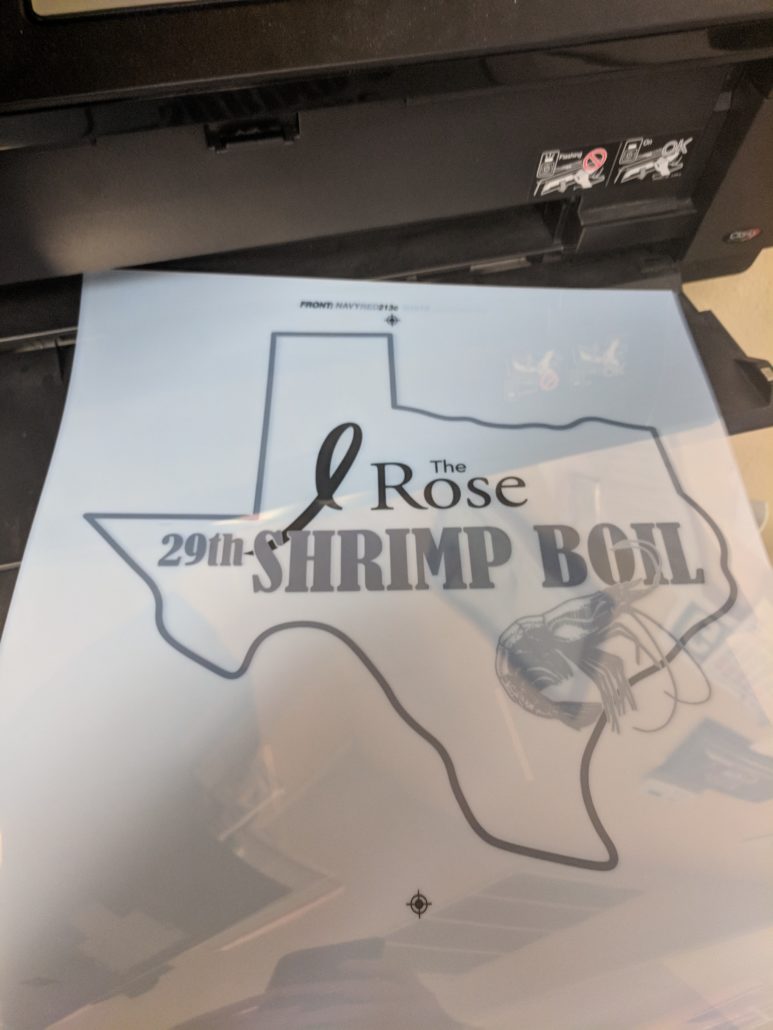

Next we print out all of the color separations onto film.

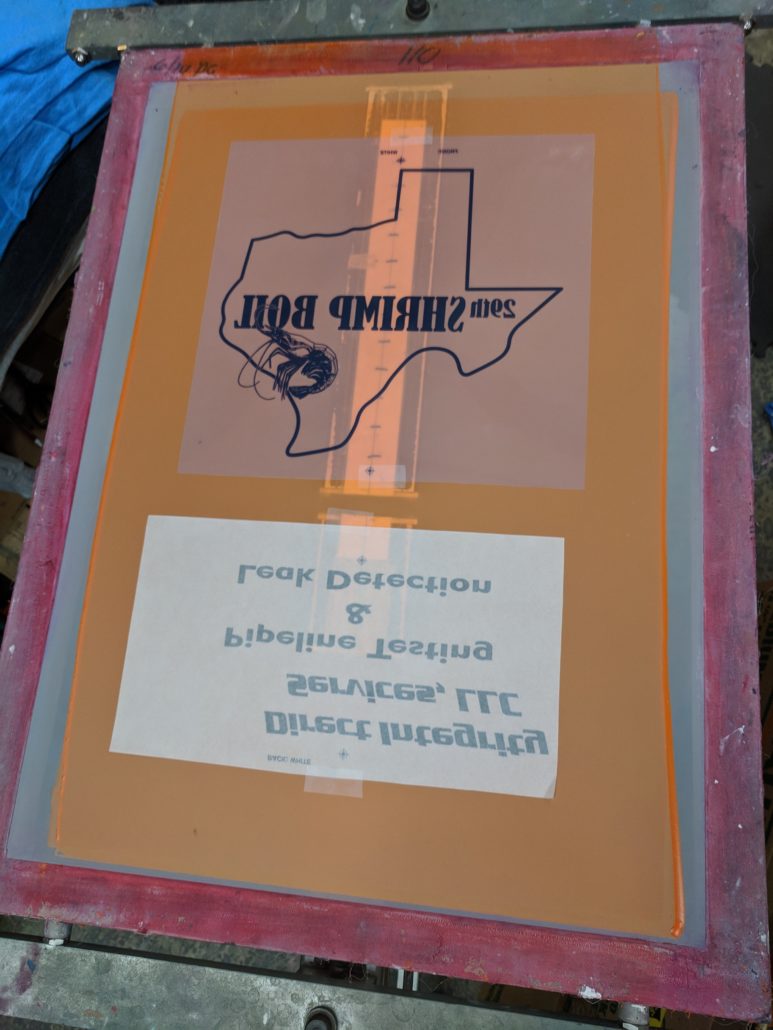

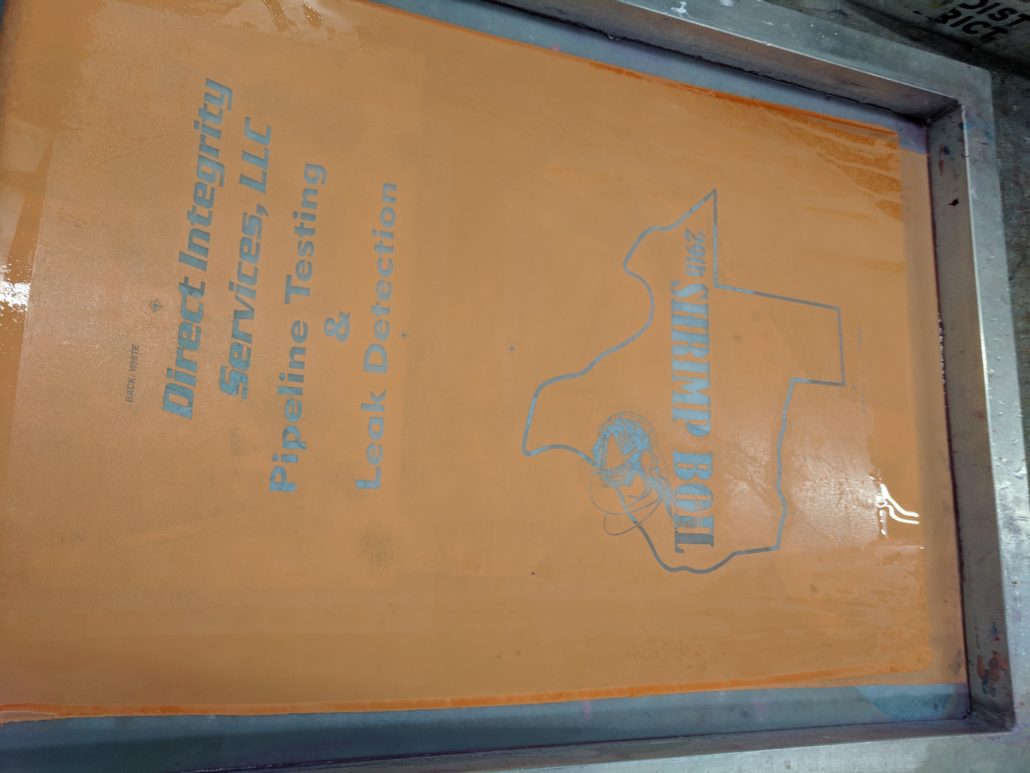

We use a machine to align all of the films to the screens in the same position.

We then use an exposure unit to expose the screens. This is basically a bright light that cures the screen everywhere except behind the black ink on the films.

After the screens are exposed we use water to wash out the images on the screens.

Once we get the water dried off, we will tape over all of the areas we do not want ink to go through.

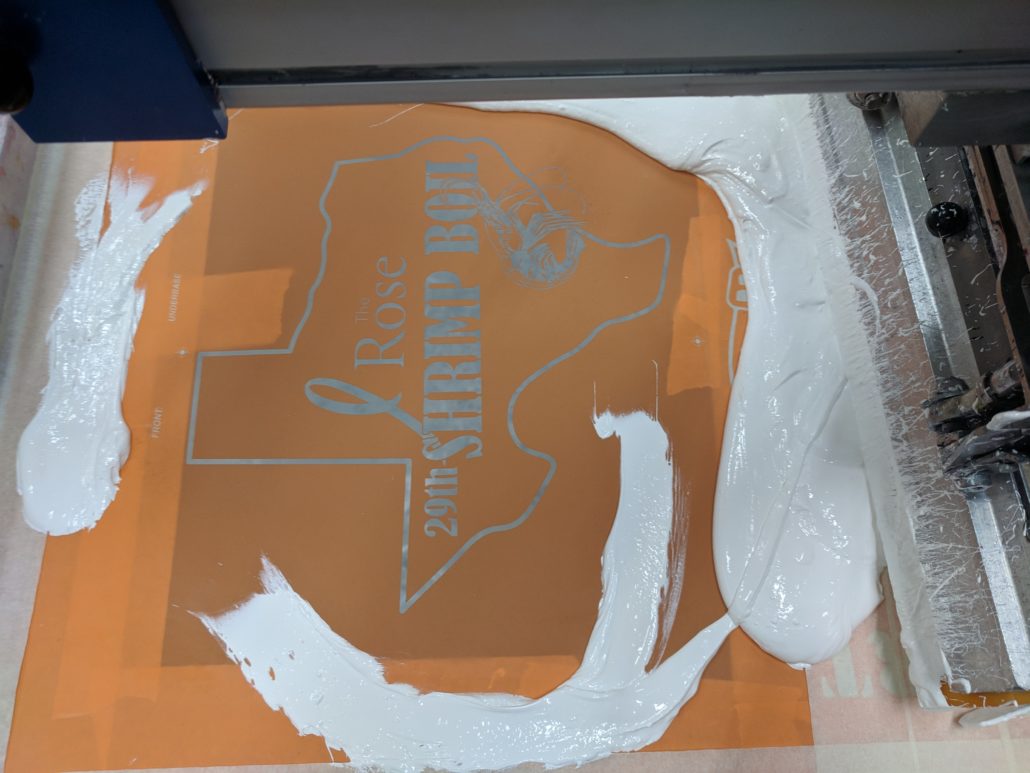

We load the screens onto the machine and add in the ink.

First we have to add adhesive to the machine to keep the shirts from sticking to the back of the screens.

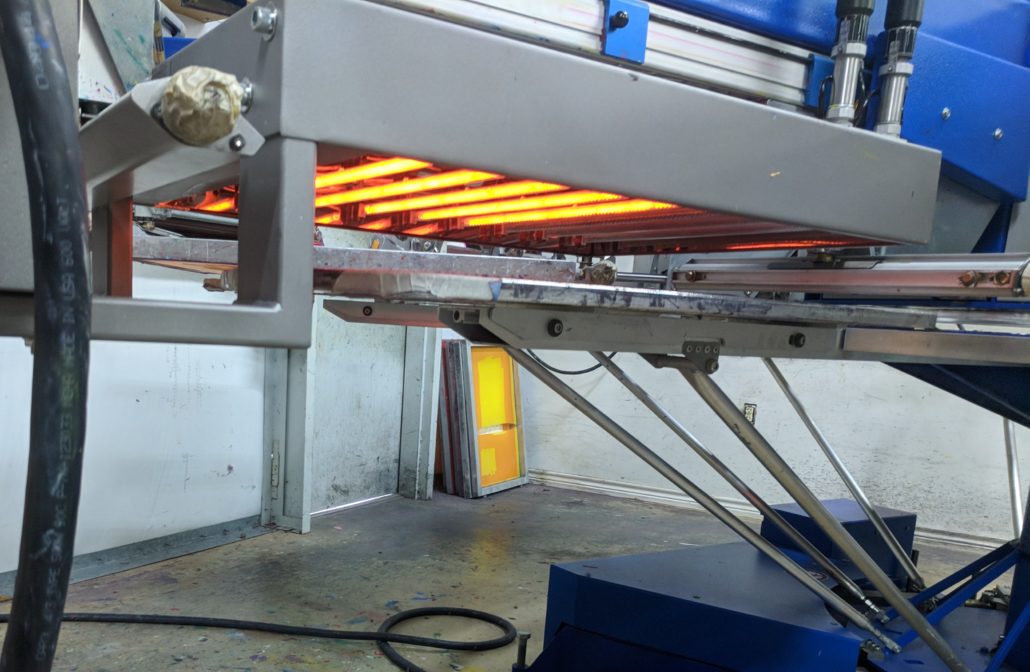

Now we have to heat up the pallets on the machine, so that the adhesive is not wet.

Once we preheat the pallets we are ready to print.

After we print the shirts, we run them through a dryer to cure the ink.

If you need some custom printed shirts we would like to help you with that! Thank you reading.